Sinteco emerges from a priceless and unrepeatable experience

that has led to a technological and application know-how

that few companies can boast.

Sinteco emerges from a priceless and unrepeatable experience

that has led to a technological and application know-how

that few companies can boast.

A HISTORY OF RESEARCH AND ECOLOGICAL AWARENESS

A HISTORY OF RESEARCH AND ECOLOGICAL AWARENESS

Sinteco has always been a leader in the research and application of new molecules in different sectors, research and application of new technologies for production processes with the ultimate goal of improving production performance, reducing the ecological/environmental impact in compliance with current regulations. Many of the most important multinationals rely on Sinteco for the development of new production technologies, particularly in the application of new flammable molecules in processes where an inert product has always been used, giving its experience that has lasted for over 30 years of applications in our different business sectors.

As early as the 1970s, the introduction of special hydrocarbons in the aerosol sector was studied/proposed and industrialised, where only CFCs and/or HCFCs harmful to ozone were used at the time. In a few years, a large part of the Italian and European market has changed the type of production from products deriving from Fluorine/Chlorine to products deriving from Petroleum (HC).

In the early 1990s the introduction of special high purity Hydrocarbons in the Plastic Material Extrusion sector such as PS-PE-PP was studied/proposed and industrialised, where only CFCs and/or HCFCs harmful to the Ozone were used at the time. In a few years, all of the Italian and European market changed the type of production from products deriving from Fluorine/Chlorine to products deriving from Petroleum (HC).

In the early 1990s the introduction of special high purity Hydrocarbons in the Plastic Material Extrusion sector such as PS-PE-PP was studied/proposed and industrialised, where only CFCs and/or HCFCs harmful to the Ozone were used at the time. In a few years, all of the Italian and European market changed the type of production from products deriving from Fluorine/Chlorine to products deriving from Petroleum (HC).

In the early 1990s, the introduction of Liquid Hydrocarbons was studied/proposed and industrialised in the rigid Polyurethane Foaming sector, where only HFC and/or HCFC were used at the time. In a few years, a large part of the European market and beyond has changed the type of production from products deriving from Fluorine/Chlorine to products of Petroleum origin with a very low GWP and better foaming performance.

In the early 1990s, the introduction of high purity Hydrocarbons was studied/proposed and industrialised in the Domestic Refrigeration sector, where only CFCs and/or HCFCs and/or HFCs were used at the time. In a few years, all of the Italian and European market changed the type of production from products deriving from Fluorine/Chlorine to products deriving from Petroleum (HC) such as R600a.

In the early 1990s, the introduction of high purity Hydrocarbons was studied/proposed and industrialised in the Domestic Refrigeration sector, where only CFCs and/or HCFCs and/or HFCs were used at the time. In a few years, all of the Italian and European market changed the type of production from products deriving from Fluorine/Chlorine to products deriving from Petroleum (HC) such as R600a.

In the early 1990s, the introduction of high purity Hydrocarbons in the Refrigeration sector and, particularly, the mobile Air Conditioning sector was studied/proposed and industrialised, where only CFC -HCFC – HFC were used at the time. In a few years the most important operators in the sector have changed the type of production from products deriving from Fluorine/Chlorine to products deriving from Petroleum (HC) such as R290. Even today, after many years, some non-EC operators are following this philosophy which has gained increasing popularity on the market over time.

In the early 90s, the introduction of low Greenhouse Effect HFCs in the XPS Eextrusion sector was studied/proposed and industrialised, where only CFCs and/or various HCFCs in mixture with other products were used at the time. In a few years, all of the European market changed the type of production from products deriving from Fluorine/Chlorine to HFC products with a very low GWP.

In the early 90s, the introduction of low Greenhouse Effect HFCs in the XPS Eextrusion sector was studied/proposed and industrialised, where only CFCs and/or various HCFCs in mixture with other products were used at the time. In a few years, all of the European market changed the type of production from products deriving from Fluorine/Chlorine to HFC products with a very low GWP.

Today, thanks to its know-how, Sinteco is working at European level to introduce new HFO molecules in different application sectors to enhance energy efficiency, improve thermal insulation and reduce environmental impact by drastically lowering the GWP.

Today, thanks to its experience of over 30 years in the application of new flammable refrigerant gases (either HFC + HFO or HC), Sinteco is working towards the industrialisation of these gases in user production processes. Providing all the plant engineering and experience in the management of an A2L or A2 or A3 flammable gas in a production department and all the technical solutions to work safely with these new flammable gases.

Today, thanks to its experience of over 30 years in the application of new flammable refrigerant gases (either HFC + HFO or HC), Sinteco is working towards the industrialisation of these gases in user production processes. Providing all the plant engineering and experience in the management of an A2L or A2 or A3 flammable gas in a production department and all the technical solutions to work safely with these new flammable gases.

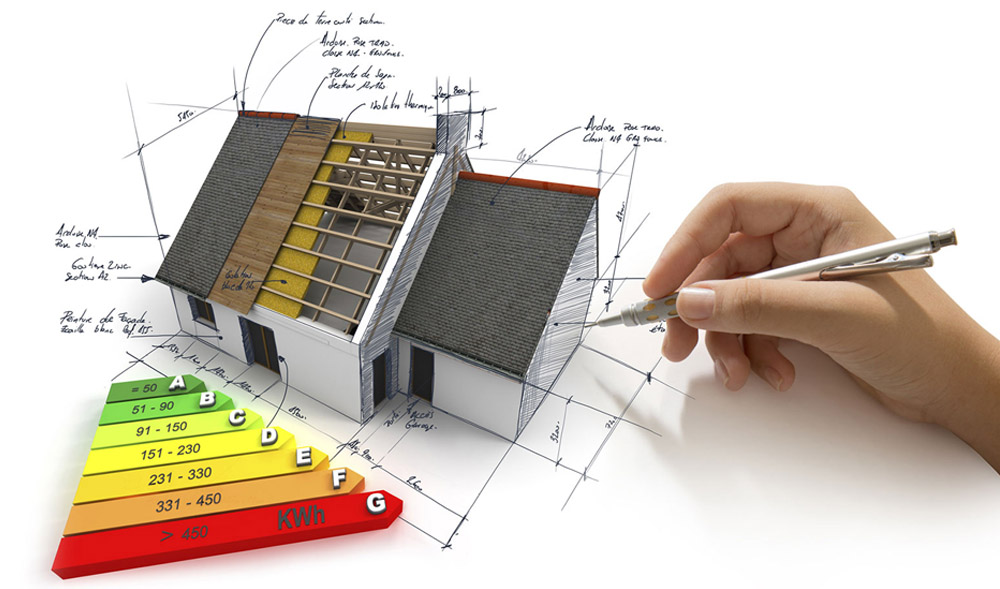

SUSTAINABLE COMMERCIAL REFRIGERATION = SAVE ENERGY

Sinteco has chosen to follow and propose the philosophy of Save Energy = Save Money. In fact, for years it has been engaged in the application and industrialisation of new molecules to improve the energy efficiency of many finished products and equipment with the aim of improving energy efficiency, in accordance with the European Eco-Design Regulations. This application research in different production processes embraces different sectors but all with the aim of improving energy performance. Particularly in Commercial Refrigeration (Display Cabinets, Refrigerated Counters, Freezers, Refrigerators, etc.) where the equipment is connected to the electricity grid, it must be able to function at its best but with the lowest possible energy consumption, therefore having an energy efficiency, following A B C Energy Class Certifications. In these productions, Sinteco applies new molecules and new production systems that allow to improve insulation, to bring more and more eco-sustainable and low-power equipment to the market. Furthermore, the volumetric capacity of these appliances has also been improved, a very important aspect for the sector.

Sinteco has chosen to follow and propose the philosophy of Save Energy = Save Money. In fact, for years it has been engaged in the application and industrialisation of new molecules to improve the energy efficiency of many finished products and equipment with the aim of improving energy efficiency, in accordance with the European Eco-Design Regulations.

This application research in different production processes embraces different sectors but all with the aim of improving energy performance. Particularly in Commercial Refrigeration (Display Cabinets, Refrigerated Counters, Freezers, Refrigerators, etc.) where the equipment is connected to the electricity grid, it must be able to function at its best but with the lowest possible energy consumption, therefore having an energy efficiency, following A B C Energy Class Certifications. In these productions, Sinteco applies new molecules and new production systems that allow to improve insulation, to bring more and more eco-sustainable and low-power equipment to the market. Furthermore, the volumetric capacity of these appliances has also been improved, a very important aspect for the sector.

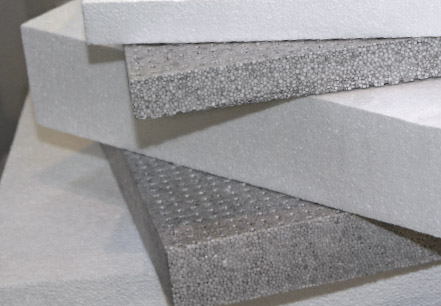

THERMAL EFFICIENCY AND ENERGY SAVING OF INSULATING MATERIALS

For many years Sinteco has assisted the most important companies in the world that produce insulating materials for the development of high thermal efficiency insulating products to make increasingly performing insulating products available to the Construction market. In the production of plastic materials such as XPS – PE – XPET or XPU – PIR, Sinteco is divulging and applying new technologies for the production and application of special molecules to increase insulation levels and achieve the purpose of ECODESIGN. In particular, this type of application is widely reflected in the Building Construction sector for the construction of increasingly eco-sustainable buildings with better insulation levels and low management consumption, but the same technology is also widely used in the production of technical products, where energy improvement is very important in the final system of use of these products. All this leads to a technological improvement, an improvement of the Energy Efficiency Class in many sectors and applications.

For many years Sinteco has assisted the most important companies in the world that produce insulating materials for the development of high thermal efficiency insulating products to make increasingly performing insulating products available to the Construction market.

In the production of plastic materials such as XPS – PE – XPET or XPU – PIR, Sinteco is divulging and applying new technologies for the production and application of special molecules to increase insulation levels and achieve the purpose of ECODESIGN. In particular, this type of application is widely reflected in the Building Construction sector for the construction of increasingly eco-sustainable buildings with better insulation levels and low management consumption, but the same technology is also widely used in the production of technical products, where energy improvement is very important in the final system of use of these products. All this leads to a technological improvement, an improvement of the Energy Efficiency Class in many sectors and applications.

These production innovations introduced by Sinteco, with the application of new molecules combined with a production technique different from the traditional one, are leading to important results in many sectors, with an improvement in performance ranging from 20 to 30% compared to traditional production.