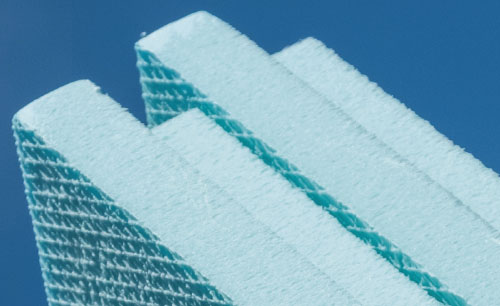

Design and Implementation of Plants for the production of extruded plastic and foam, such as for example Polystyrene Foam insulating Sheets (XPS), Polystyrene trays (Food), polyethylene Profiles, polyethylene Pipes with Copper, polyethylene or polypropylene Film, XPE polyethylene Sheets and slabs or blocks of PET (XPET) and other extruded plastic foams.

The above plants include Storage, Transfer and Distribution of low and high pressure Blowing Gases (such as, for example: R152a, R152a / DME, R134a, Isobutane, DME, Alcohol, Cyclopentane, DME / Isobutane, HFO, Solstice GBA, Solstice LBA, etc.

Our technology lends itself to both non-flammable and flammable products.

Specifically, in addition to the above:

- “Safety” systems: Forced air exhaust and gas detection system with control SW in environments where flammable and/or dangerous products are used (Production – Finished product storage warehouses).

- Flammable/explosive Eexd – Eexi gas detection.

- Foam chip-powder storage and processing plants.

- Electro-Pneumatic safety command and control systems.

- Safety Electrical Panels for production process control

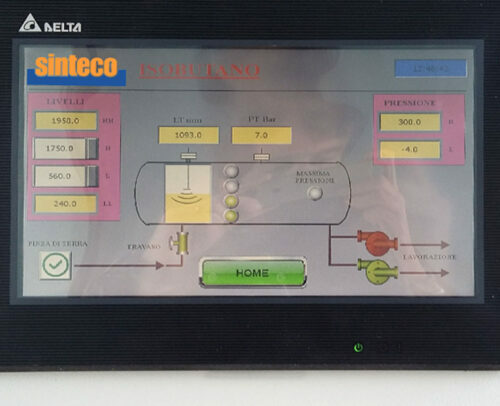

- SW systems with operator interface PLC.

Standardised and certified systems according to:

- M.D. May 14, 2004 – LPG DEPOSITS (Less than 13mc): Approval of the fire prevention technical rule for the installation and operation of liquefied petroleum gas deposits with a total capacity not exceeding 13 cubic metres (as amended).

- M.D. October 13, 1994 – LARGE LPG DEPOSITS (Over 13mc): Approval of the fire prevention technical rule for the design, construction, installation and operation of LPG deposits in fixed tanks with a total capacity exceeding 5 mc and/or in mobile containers with a total capacity exceeding 5,000 kg.

- PED Directive 2014/68/EU on the harmonisation of the laws of the Member States relating to the making available on the market of pressure equipment.

- ATEX Directive 2017/34/EU concerning the harmonisation of laws in Member States relating to equipment and protective systems intended for use in a potentially explosive atmosphere.

- Classification of areas in accordance with the “ATEX” regulation.

Design and Implementation of Plants for the production of extruded plastic and foam, such as for example Polystyrene Foam insulating Sheets (XPS), Polystyrene trays (Food), polyethylene Profiles, polyethylene Pipes with Copper, polyethylene or polypropylene Film, XPE polyethylene Sheets and slabs or blocks of PET (XPET) and other extruded plastic foams.

The above plants include Storage, Transfer and Distribution of low and high pressure Blowing Gases (such as, for example: R152a, R152a / DME, R134a, Isobutane, DME, Alcohol, Cyclopentane, DME / Isobutane, HFO, Solstice GBA, Solstice LBA, etc.

Our technology lends itself to both non-flammable and flammable products.

Specifically, in addition to the above:

- “Safety” systems: Forced air exhaust and gas detection system with control SW in environments where flammable and/or dangerous products are used (Production – Finished product storage warehouses).

- Flammable/explosive Eexd – Eexi gas detection.

- Foam chip-powder storage and processing plants.

- Electro-Pneumatic safety command and control systems.

- Safety Electrical Panels for production process control

- SW systems with operator interface PLC.

Standardised and certified systems according to:

- M.D. May 14, 2004 – LPG DEPOSITS (Less than 13mc): Approval of the fire prevention technical rule for the installation and operation of liquefied petroleum gas deposits with a total capacity not exceeding 13 cubic metres (as amended).

- M.D. October 13, 1994 – LARGE LPG DEPOSITS (Over 13mc): Approval of the fire prevention technical rule for the design, construction, installation and operation of LPG deposits in fixed tanks with a total capacity exceeding 5 mc and/or in mobile containers with a total capacity exceeding 5,000 kg.

- PED Directive 2014/68/EU on the harmonisation of the laws of the Member States relating to the making available on the market of pressure equipment.

- ATEX Directive 2017/34/EU concerning the harmonisation of laws in Member States relating to equipment and protective systems intended for use in a potentially explosive atmosphere.

- Classification of areas in accordance with the “ATEX” regulation.